If you are in the market for a rail scale, purchase price is determined by a series of decisions that you must make. If you do not need a legal for trade rail scale, there are a number of options for you.

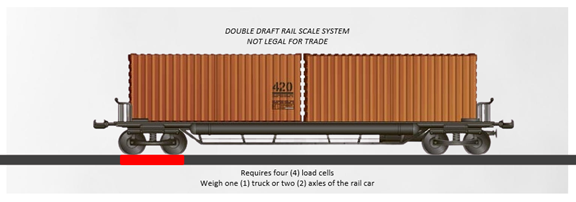

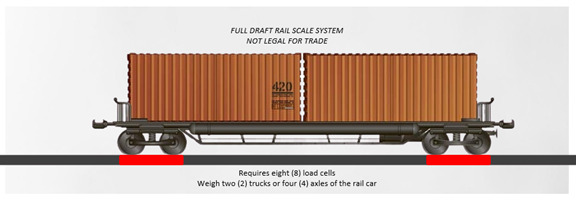

Avery Weigh-Tronix, Rice Lake, SAI and other rail scale manufacturers offer heavy-duty, modular checkweighing rail sections that can be installed to create a scale system. These rail sections replace current lengths of rail with a new piece of rail with an integrated load cell. The full rail scale system typically contains four or eight rail sections, wiring, and a controller or indicator. Additional options include rail weight software, printer, and remote scoreboard. These rail scales do not require a concrete foundation, and the system is relatively straightforward. As a result, flexibility and minimal downtime are considered key advantages. You are able to ensure optimal safe loads, prevent overload fees and verify product weights.

Alternatively, you can install a legal for trade scale module without following all the foundation requirements that a legal for trade scale requires. This saves potential rail scale owners substantially on both site work and foundation work.

Depending on what type of scale you choose, non-legal for trade rail scale equipment can range from $30,000 to over $100,000.

Rail scales will have the different requirements depending on what it is you are looking to do with your operation. Our Learning Hub is a great resource for various articles with a bit more added detail. Be sure to check out our article “Do I Need A Legal For Trade Rail Scale” to help you decide which way to go during your rail scale journey.

SO HOW MUCH DO RAIL SCALES COST?

For pricing guidelines for non-legal for trade rail scales, "How Much Does A Non Leagal For Trade Scale Cost?"

For pricing guidelines for legal for trade rail scales, "How Much Does A Legal For Trade Scale Cost?"

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.