Conveyor belt scales, also known as belt scales or weigh belt scales, are an essential tool for a wide range of industries. These scales are used to measure the weight of materials as they are transported on a conveyor belt, providing an accurate and continuous weight measurement.

Belt scales are an important part of most bulk material handling facilities. A conveyor belt scale weighs items on a moving conveyor belt by weighing the belt load and measuring belt speed.

how does it work?

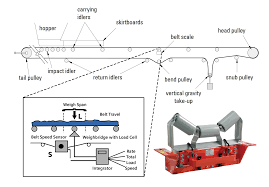

Conveyor belt scales consist of a weigh bridge, a load cell, and a belt speed sensor. The weigh bridge is mounted underneath the conveyor belt, and the load cell measures the weight of the material on the belt. The belt speed sensor is used to measure the speed of the belt, and the weight and speed measurements are combined to calculate the flow rate of the material.

Benefits

One of the key advantages of conveyor belt scales is their ability to provide a continuous weight measurement. Unlike static scales, which require the material to be weighed individually, conveyor belt scales can provide a constant weight measurement as the material moves along the conveyor belt. This makes them ideal for applications where a continuous flow of material is being transported, such as in mining, quarrying, and other bulk material handling operations.

Another advantage of conveyor belt scales is their accuracy. These scales are designed to provide highly accurate weight measurements, with a resolution of up to 1/10,000 of the load being measured. This level of precision is essential for ensuring the efficiency and safety of industrial operations.

Closing words

Overall, conveyor belt scales are an essential tool for a wide range of industries. They provide a continuous and accurate weight measurement, helping to ensure the efficiency and safety of material handling operations.

At American Scale we strive to bring you informed and useful content on all things scale systems related, including products from the top scale manufacturers. Be sure to check out our truck scale articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership. Also, take a look at our “Common Problems With Bench Scales'', to help prolong the lifespan on your scale.