Truck Scale Buyers -

Don’t Make These 5 Common Mistakes

As a truck scale buyer, you need to make sure you avoid these common pitfalls. Too often one of these mistakes can torpedo and entire truck scale project. Don’t let that happen to you; review these top 5 mistakes and how to avoid them.

#1 Wrong location

Where to put your truck scale. Don’t put it in a low-lying area. Low lying areas are where all the water on the property will collect or at a minimum run through. Water and scales are never a good combination. Even with today’s hermetically sealed load cells, there are still multiple weak points on scale electronics that water will damage.

Second, a low-lying area will collect build-up. What do we mean by build-up? Build-up is rocks, dirt, sand, or any other material that will wash or blow under the scale. This build-up will cause major scale weighing issues. The scale platforms overtime will begin to sit on the built-up dirt and not the load cells. What does this lead to? A scale that weighs light and not accurately.

Bottom-line consider the topography when selecting a location for you truck scale.

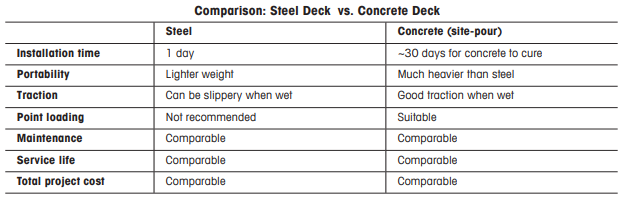

#2 Wrong Foundation Type

Too often truck scale buyers think they want a pit style foundation. Pit foundations have their place, but they are the exception and not the norm. A pit foundation sounds good in theory since it doesn’t require concrete ramps, take up less space, etc. But understand a true pit foundation will cost in concrete work 2-2.5x the cost of an above-ground foundation.

In addition, a pit scale is covered by confined space entry regulations, meaning the cost for maintenance goes up significantly. A concrete pit for a scale is like a big bucket on your property that will collect water. This means a sump pumping system must be installed and that moisture can begin to rust the scale from the underside faster.

Bottom-line, unless you need a pit foundation for a specific reason choose an above- ground. You and your scale will be happier.

To learn more about the different truck scale foundation types see this blog post.

#3 Wrong Scale Installation Company / Dealer

The old saying you cant get all three (fast, cheap, and good quality) is applicable when selecting a truck scale installer. Whatever you do ensure you have good quality. A truck scale is a 25-year investment that can be ruined if installed incorrectly. Make sure your installer is certified/licensed in your state, has required insurance (WC, GL,etc.), and have a track- record of previous installations that they can show you.

You can mitigate all the other mistakes but if your scale is installed incorrectly the rest of your work & planning will be useless.

#4 Poor Project Planning

As with any construction project having a good plan is paramount to success. Your project plan should be a partnership between you and your scale installation company. There are a number of moving pieces when installing a new truck scale. When will the scale arrive? Who is coordinating the crane? Is the foundation poured and cured? Are the conduits for cabling/wires laid out? Is there 120VAC power run to where the remote display will go? Do you need building permits? Will the scale connect to a computer? The questions go on and on. Lean on your scale installer to lead the project but understand as the buyer you carry many of the responsibilities of whether the installation timeline is met.

As the buyer you will most likely need to provide 120VAC power to power the scale; without power the scale installer cannot complete installation of the scale, calibration of the scale, or set-up of the indicator. Bottom-line, select the right scale installation company and build a strong partnership with them to ensure an on-time, on-budget truck scale installation.

#5 Wrong Scale

Selecting the correct scale for your project is foundational. We have dedicated a couple whole articles to all the options you must select (deck type, scale length, scale width, electronic or hydraulics, digital or analog, etc.). One focus point is buying a scale that is paired to number of trucks you plan to weigh daily and their average weight.

Do not buy a light or medium duty scale if you plan to pound150 logging trucks each weighing 90k lbs+ everyday across your scale. Buying a heavier duty scale will never hurt you.