Livestock Scales For Beginners.

Livestock scales are an important part of farming. The scales are an integral part of the food production process. There is a lot that goes into livestock scales and how they operate. This article will take a deep dive into livestock scales and how they work in food production.

What is a livestock scale?

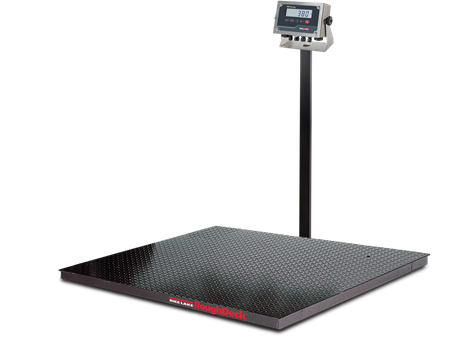

Livestock scales are scales that are either mechanical or electronic with a design for weighing large animals like cattle. These scales have a pen with animal safety design. Other than farms and ranches, there are other places that use livestock scale such as zoos and animal rescues.

Livestock scales have a durable design. The components are corrosion resistent and has a washdown surface for easy cleaning. When it comes to optioning out your scale deck, you have several choices to choose from. Some of those choices include steel, concrete or rubber-coated decks. The deck surfaces help keep the animals comfortable and safe while weighing. Depending on the scale’s location will determine which scale is best. If your scale is located outside, then there are various hazards that can affect your scale. Scales can get dirty quickly, having a washdown schedule.

The different types of livestock scales

Livestock scales provide a safe environment to weigh the animals. The scale design with pen-like are available with stationary, mobile and portable alternatives. Manufacturers provide individual and group livestock scales in various sizes. There are a lot of custom options as well. There will also be a different weight, weighing technology and display choices.

Mobile Livestock Scales:

Mobile animal scales (MAS) are designed to be transported to the location of the animals to be weighed. The scales are designed with durability in mind. These scales will also be equipped with steel pens suspended on load cells.There is also a cage that is installed to help keep the animals safe and locked in during transport. This cage can be locked down to the frame while transporting the animals. The reasoning for this design is because it prevents cage movement and load cell damage during transport. The mobile livestock scale is a good choice if you have to actually go to the animals yourself.

Portable Livestock Scales:

Portable Animal Scales (PAS) are designed to be transported to various weighing sites. The majority of portable livestock scales are suitable to be used in harsh and unpredictable conditions of multiple site weighing. They can have a deck and a pen side for a smoother loading and unloading process for the animals.

Stationary Livestock Scales:

Stationary Animal scales (SAS) are designed to be set up at one location, to which the animals can be guided to the scale to be weighed. One thing to note about stationary livestock scales is that they're available in a myriad of sizes to hold the amount of livestock you need to be weighed. The cool thing about stationary scales is that they combine the accuracy of fully electronic weighing technology coupled with steel weighbridge designs that are typically found in truck scales.

What makes up a livestock scale?

Livestock scales are made up of several components. There is a deck that is surrounded by pen fences, which is then suspended on a base frame on top of four load cells. Portable scales are equipped with an air suspension system which makes the scale lift and lower to allow for the animals to be easily loaded and unloaded. The majority of animal scales are pen configurations that provide a safe environment for animal weighing. These pen-like scales are accessible with stationary, mobile and portable alternatives. Manufacturers also provide scales that are designed for individual and group animal weighing. Depending on where and how the scale will be stored will help you determine whether to have surfaces for washdown.

What is Shrink?

Shrink is the quantity of weight-loss of animals when traveling on an off-site scale. When working with livestock, farmers will spend the majority of their time managing their cattle’s diet to ensure that they gain as much weight as possible by the time it's ready to go to the market. When the cattle is transported, held or gathered, it cuts into their time for eating. When this happens the animals start losing weight. This weight loss is referred to as shrinkage. There are various factors that can influence the amount of shrinkage you will have. Understanding that these factors are present and important to how you manage your livestock and ensuring minimum shrinkage.

Regardless of which livestock you are working with, minimizing shrinking losses is paramount in maximizing the bottom line. There have been various studies that have shown an average weight loss of 6 percent. With the introduction of mobile and portable scales, shrinkage has been reduced to about 2%, with a profit increase of 6%. The choice of a mobile over a stationary livestock scale could be decided by the increased profitability. Below is a list of tips that can help you decrease shrinkage during the weighing process.

Reducing Shrink

Shrink is most often measured from the time an animal leaves the ranch or farm, to the point the animal is weighed at the destination. The shrink comes as a result of time off feed and water and the stress of handling and hauling. There is also the factor of temperature, weather changes, environment, feed changes. These are all factors that can contribute to shrink. Below are some tips on how you can help decrease shrink:

Understand what upcoming weather will be like. Checking the forecast, reading an almanac will help you to avoid transporting cattle in less than ideal conditions.

Transport livestock slowly when handling and loading.

Avoid exposing animals to unfamiliar environments without preconditioning.

Perform regular service on your scales to help avoid downtime.

Avoid overcrowding of your livestock. This can cause stress and discomfort during transport.

Avoid long transport trips and also provide time to allow cattle to rest.

Try to transport animals on smooth roads and avoid rough and uneven surfaces.

Provide feed and water for the animals.

Be sure to withhold water up to 3 hours before shipping.

Benefits of livestock scales

Livestock scales will hold a lot of benefits over other scales that can measure heavy weight. In this section we will go through the benefits of owning a livestock scale and how it helps your overall livestock production.

Accuracy: Livestock scales are designed to be extremely precise. Since you are dealing with animals, that means that weights can fluctuate, thus affecting the bottom line. The precision and accuracy of a livestock scale is very important and integral to your operation. Ensure that your scales are maintained and properly calibrated.

Durability: Livestock scales need to be durable to ensure that they can handle the difficult livestock circumstances and in handling the heavy loads. These scales are intended to be very durable and capable of handling the hazards of handling livestock. These scales are designed to manage animal kicking and other environmental hazards over other industrial scales.

Evaluation: Livestock scales are equipped with the ability to evaluate weights at different phases of their life-scale. The information collected can be used and analyzed to assess feedlots and annual weights averaged daily increase (ADG), and daily weight gains (WDA). With livestock scales you are able to evaluate the overall performance of your livestock.

Feed & Medicine Monitoring: When feeding and medicating your livestock, knowing what the exact quantity of food and medicine, is essential to the overall health of your livestock. Livestock scales can assist in correctly calculating the feed/medicine, which in turn helps keep you from giving the animals exactly what they need in food and medicine.

Animal Comfort: Scales for livestock are intended to comfortably accommodate different animal types. Low profile scales are great for loading and unloading animals due to the convenience factor of not having to step up a high distance.

Simple to Handle: You need less work to use livestock scales because they are simple to manage. They have an inner memory that makes the history of different animals simpler to evaluate.

Ease of use: The cattle scales are constructed from flat or concrete wood decks that make things easy to transport. There are several features that have ease of use in mind, including memory parts and weight information collection.

Customization:A lot of livestock scales are highly customizable to meet your needs. Some accessories include digital indicators, portals, load bars, surfaces and many more. All of the custom options available are designed to each unique client.

Conclusion

Livestock scales have a lot of intricacies to them and it is easy to get lost on each aspect. When it comes down to it, as a farmer or rancher you will want to protect your bottom line. Researching and purchasing the right livestock scale for you will take some time, but it is well worth it. Regardless of having a small farm or a large scale livestock farm, the significance of accurate measurement of animal performance is paramount when maximizing your profits through the entire process. If you want to know more about the cost of livestock scales, be sure to check out our article about livestock scales pricing.