Conveyor belt scales are critical components of various industries, from mining and agriculture to manufacturing and logistics. They play a vital role in accurately measuring and controlling the flow of materials, ensuring efficient operations, and optimizing resource utilization. To maintain the reliability and accuracy of conveyor belt scales, regular maintenance is essential. This article will delve into the intricacies of conveyor belt scale maintenance, covering the importance of maintenance, common maintenance tasks, and best practices to ensure seamless operations.

The Importance of Conveyor Belt Scale Maintenance

Conveyor belt scales are used for a wide range of applications, including measuring bulk materials, monitoring production processes, and managing inventory. Their significance lies in their ability to provide real-time data that helps businesses make informed decisions, improve efficiency, and control costs. However, without proper maintenance, these scales can become inaccurate, leading to financial losses, production inefficiencies, and safety hazards. Here's why conveyor belt scale maintenance is crucial:

Accuracy and Consistency: Conveyor belt scales must provide precise and consistent measurements to support accurate record-keeping and process control. Regular maintenance ensures that the scale remains calibrated and reliable.

Compliance: Many industries, such as mining and agriculture, are subject to regulatory standards and trade certifications. Proper maintenance helps meet these requirements, avoiding potential fines or legal issues.

Cost Efficiency: Accurate measurements enable companies to optimize resource use, reduce waste, and minimize operational costs. Unreliable scales can lead to overuse or underuse of materials, resulting in financial losses.

Safety: Malfunctioning conveyor belt scales can create safety hazards. For instance, an inaccurate measurement may lead to overloading, potentially damaging equipment or causing accidents.

Common Conveyor Belt Scale Maintenance Tasks

Maintaining conveyor belt scales involves a series of tasks aimed at ensuring their proper operation. While the specific requirements may vary depending on the scale's type, here are some common maintenance tasks:

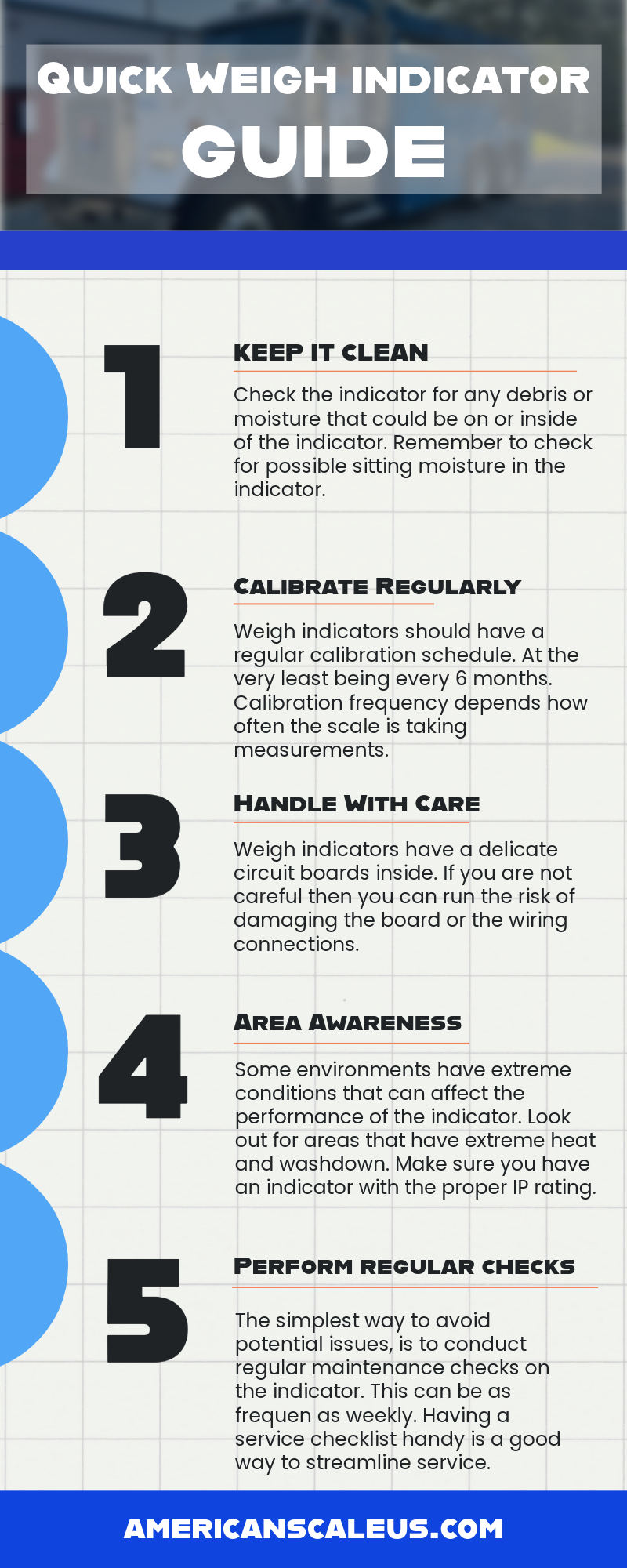

Regular Calibration: Calibration is the process of adjusting the scale to ensure it provides accurate measurements. Calibration should be performed at scheduled intervals or whenever there is a significant change in the operating conditions.

Cleaning and Inspection: Regularly inspect the scale for debris, material buildup, or damage. Clean the conveyor belt and scale components to prevent interference with the measurements.

Belt Alignment: Proper alignment of the conveyor belt is crucial for accurate measurements. Misalignment can result in uneven material distribution and measurement errors.

Sensor Check: Inspect sensors, load cells, and other electronic components for damage or wear. Ensure they are properly connected and functioning.

Belt Tension: Maintain the correct tension in the conveyor belt. Too much or too little tension can affect the scale's accuracy and lead to premature wear.

Roller and Idler Inspection: Check rollers and idlers for wear and damage. Replace any worn or damaged components to prevent belt misalignment.

Sealing: Ensure that the scale is adequately sealed to protect it from environmental factors such as moisture, dust, and temperature fluctuations.

Software Updates: If your conveyor belt scale relies on software for data processing, keep it up to date to benefit from improvements and bug fixes.

Best Practices for Conveyor Belt Scale Maintenance

To ensure the longevity and accuracy of conveyor belt scales, consider implementing these best practices:

Establish a Maintenance Schedule: Create a comprehensive maintenance schedule that includes regular inspections, calibrations, and cleaning. Stick to this schedule diligently.

Document Maintenance Activities: Keep detailed records of all maintenance activities, including calibration results, repairs, and replacements. This documentation can be valuable for compliance and troubleshooting.

Train Personnel: Train your staff on proper maintenance procedures and safety protocols. Ensure that they understand the importance of their role in scale maintenance.

Use Quality Components: When replacing parts, opt for high-quality, manufacturer-recommended components to maintain the scale's accuracy and reliability.

Monitor Performance: Implement a monitoring system that continuously tracks the scale's performance. This can help detect issues early and prevent costly downtime.

Emergency Plan: Have a contingency plan in place in case the scale experiences a critical failure. This plan should include procedures for shutting down operations and addressing safety concerns.

Conclusion

Conveyor belt scales are indispensable tools for industries that rely on material handling and production processes. Proper maintenance of these scales is essential to ensure their accuracy, efficiency, and safety. By adhering to a well-defined maintenance schedule, performing regular inspections, and following best practices, businesses can maximize the benefits of conveyor belt scales while minimizing the risk of inaccuracies, downtime, and costly repairs. In doing so, they can maintain a competitive edge in their respective industries and enhance their overall operational efficiency.